Unlocking the Secrets of Multi Axis CNC Machines with 10 Essential Tips

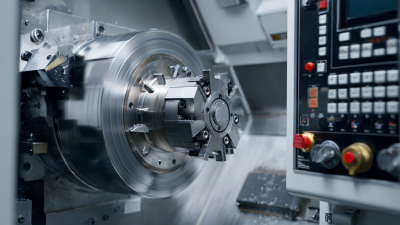

In the realm of modern manufacturing, the multi axis CNC machine stands out as a pivotal tool that enhances precision and efficiency across various industries. These sophisticated machines operate on multiple axes, allowing for complex geometries and intricate designs that were once deemed impossible with traditional machinery. However, mastering the intricacies of a multi axis CNC machine can be daunting for even the most experienced operators.

This article aims to demystify the operation and capabilities of these advanced machines by presenting ten essential tips that can significantly boost machining proficiency and output quality. From understanding the software interface to optimizing tool paths and materials, these insights will provide you with a comprehensive guide to unlocking the full potential of your multi axis CNC machine, ensuring you stay ahead in a competitive landscape.

Understanding the Basics of Multi Axis CNC Machines

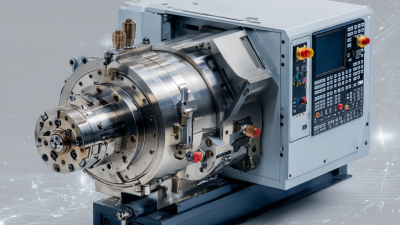

Multi-axis CNC machines have transformed the landscape of machining by enabling intricate designs and high-precision components. Understanding the basics of these machines is vital for anyone looking to leverage their capabilities. Multi-axis machining involves operating the tool on multiple axes simultaneously, which enhances efficiency and accuracy. For example, five-axis machines can move the tool across three linear axes and around two rotational axes, allowing for the machining of complex geometries that would be impossible with traditional milling machines.

Recent advancements in CNC technology highlight the need for precise programming and error identification. A new test developed for five-axis machine tools aims to pinpoint geometric and thermal errors, ensuring consistent performance during machining operations. Additionally, insights into toolpath generation algorithms reveal that tailored paths can optimize the machining of diverse materials, improving overall quality. As industries move towards more intricate designs, mastering the fundamentals of multi-axis CNC machines will be key to remaining competitive in manufacturing. Emphasizing precision and adaptability can significantly enhance production workflows and outcomes.

Essential Maintenance Tips for Optimal CNC Machine Performance

Maintaining a multi-axis CNC machine is crucial for ensuring optimal performance and longevity. According to a report by the Association for Manufacturing Technology, proper maintenance can increase equipment lifespan by up to 30%. This highlights the importance of regular checks on components such as the spindle, ball screws, and linear guides. Operators should schedule routine inspections and cleanings to eliminate contaminants that could affect precision and accuracy. Implementing a maintenance log can also aid in tracking machine performance and identifying issues before they escalate.

Another essential aspect of maintenance is lubrication. A study by the National Institute of Standards and Technology suggests that proper lubrication practices can reduce friction and wear, resulting in a 20% increase in energy efficiency for CNC machines. It is vital to follow the manufacturer's specifications regarding lubricant types and application frequency. This not only enhances the machine's operational efficiency but also improves the quality of the finished products, ensuring that manufacturers can meet stringent quality standards. Regular training for operators on maintenance protocols can further enhance machine reliability and productivity.

Unlocking the Secrets of Multi Axis CNC Machines with 10 Essential Tips

| Tip | Description | Frequency of Maintenance | Expected Outcome |

|---|---|---|---|

| Regular Lubrication | Ensure all moving parts are adequately lubricated to reduce wear. | Monthly | Improved machine longevity and performance. |

| Check Axis Alignment | Verify that all axes are properly aligned to ensure accuracy. | Quarterly | Increased machining precision. |

| Replace Worn Parts | Identify and replace parts that show signs of significant wear. | As Needed | Reduced downtime and improved functionality. |

| Software Updates | Regularly update software to the latest version for bug fixes and new features. | Bi-Annually | Enhanced performance and security. |

| Clean Dust and Debris | Regularly clean the machine to prevent dust build-up. | Weekly | Better working conditions and aesthetics. |

| Monitor Temperature | Keep an eye on machine temperature to prevent overheating. | Daily | Prolonged lifespan of components. |

| Inspect Electrical Connections | Check and secure all electrical connections to ensure proper operation. | Monthly | Reliable machine operation. |

| Adjust Feed Rates | Optimize feed rates for different materials for best performance. | As Needed | Improved efficiency. |

| Perform Tool Changes | Regularly check and replace tools to maintain cutting quality. | As Needed | Consistent quality of output. |

| Document Maintenance | Keep records of all maintenance performed for future reference. | Ongoing | Easier tracking of machine health. |

Choosing the Right Tools for Multi Axis CNC Operations

When choosing the right tools for multi-axis CNC operations, it is crucial to consider both the machine's capabilities and the specific requirements of the materials being machined. Multi-axis CNC machines excel in aerospace and automotive applications, where precision and access to various angles are paramount. Tools designed for these environments should accommodate high wear and heat resistance, particularly when working with materials like stainless steel or titanium.

Moreover, leveraging advanced software solutions can significantly enhance the efficacy of CNC machining processes. Recent developments in CNC toolpath simulation offer improved speed and accuracy, allowing for better planning and execution of complex designs. Such integrations enable machinists to optimize their operations, ensuring that they can efficiently create intricate parts while maintaining superior quality standards. By carefully selecting tools and utilizing the latest technology, machine shops can unlock the full potential of their multi-axis CNC machines.

Programming Techniques to Enhance CNC Machining Efficiency

Effective programming techniques are crucial for maximizing the capabilities of multi-axis CNC machines. One essential tip is to fully understand the machine's kinematics and limitations. This knowledge allows programmers to create efficient toolpaths that prevent collisions and ensure smooth transitions between operations. Additionally, simplifying complex geometries can significantly reduce machining time while maintaining part integrity.

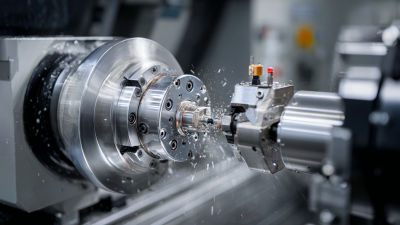

Another key technique involves the strategic use of tool selection and optimization. Choosing the right tooling for each specific task not only enhances the quality of the finished product but also contributes to longer tool life, reducing downtime for maintenance. Combining this with advanced programming features like adaptive feed rates and toolpath smoothing can further enhance efficiency. Utilizing CAM software with built-in simulations can help visualize tool movements and identify potential issues before actual machining begins, ultimately leading to more precise and effective production processes.

Common Mistakes to Avoid When Using Multi Axis CNC Machines

When operating multi-axis CNC machines, avoiding common pitfalls is essential for enhancing precision and efficiency. One frequent mistake is neglecting proper calibration of probe parameters and rotary axis locations. Utilizing effective on-machine measurement (OMM) systems to regularly check these parameters can dramatically reduce machine motion errors, thus improving overall productivity. Additionally, many operators overlook the significance of maintaining tooling solutions, including ceramic end mills and diamond-coated tools, which can lead to suboptimal performance and increased wear. Ensuring that tooling is appropriate for the specific applications can enhance the machining process's effectiveness.

Another critical area is understanding temperature-sensitive zones in CNC operations. Implementing a visualized temperature-sensitive area selection method can help operators identify and manage potential thermal effects on machining quality. Furthermore, the integration of advanced simulation software allows for faster programming and the creation of digital twins that enhance accuracy in toolpath simulation. By addressing these common mistakes and leveraging modern technologies, operators can significantly improve the reliability and outcomes of their multi-axis CNC machining processes.

Related Posts

-

Understanding Import and Export Certifications for the Best CNC Turning Machine in Today's Market

-

Challenges Associated with Choosing the Best CNC Milling Machine for Your Needs

-

Top 10 Innovative CNC Machine Parts You Didn't Know You Needed

-

Exploring the Best CNC Machine Alternatives for Your Manufacturing Needs

-

Exploring the Top 5 Examples of Best CNC Lathe Machines for Global Buyers

-

How to Optimize Production Efficiency with CNC Turning Centers