What is the Impact of the Best CNC Machine on Global Manufacturing Efficiency

The impact of CNC machines on global manufacturing efficiency is profound and far-reaching, reshaping production processes across various industries. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.2 billion by 2026, growing at a CAGR of 6.7% from 2021. This rapid advancement is attributed to the increasing demand for precision and automation in manufacturing.

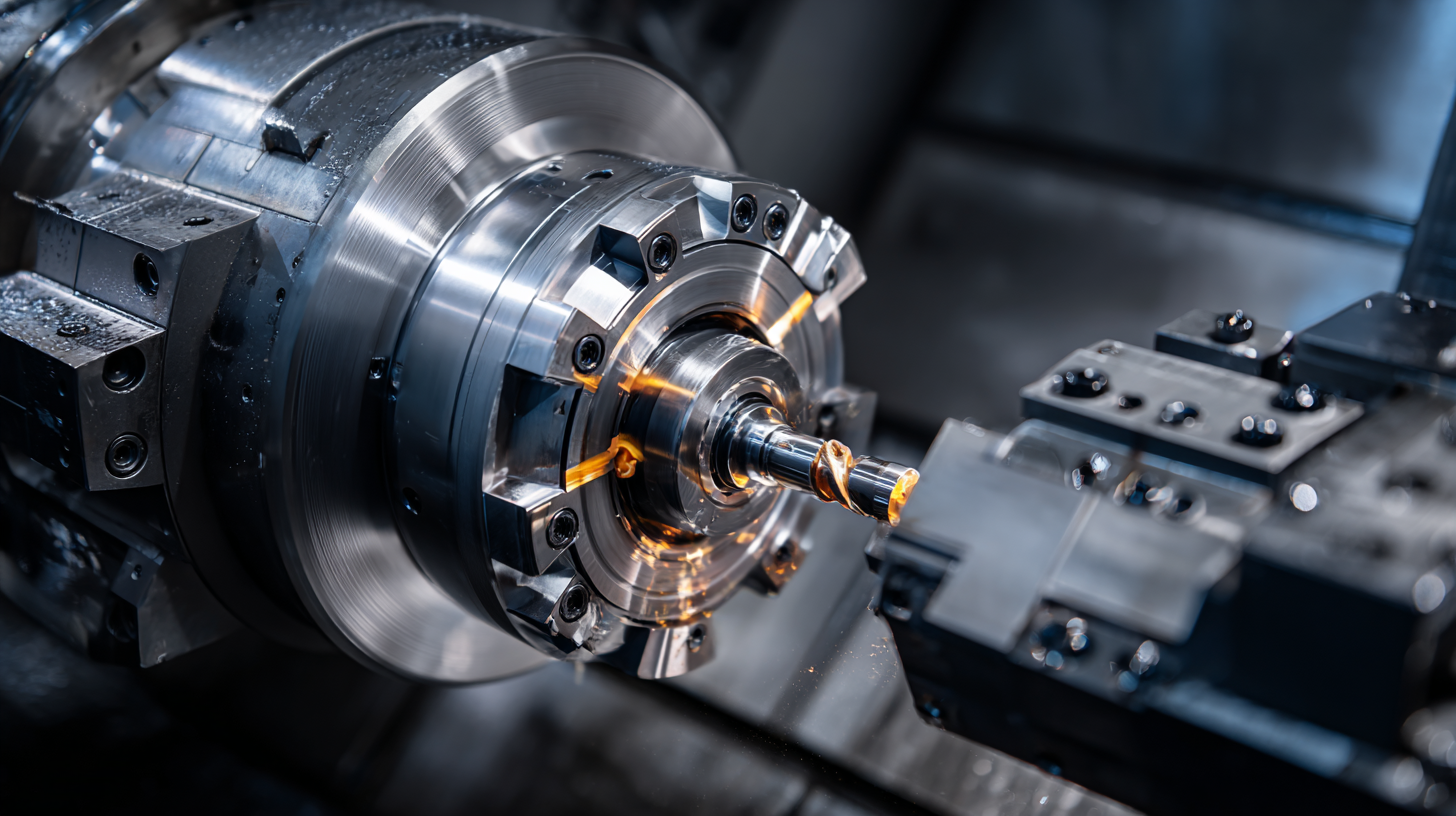

CNC machines, known for their ability to produce intricate parts with minimal human intervention, enhance productivity while significantly reducing waste. In fact, the National Institute of Standards and Technology (NIST) estimates that the adoption of CNC technology can reduce production time by as much as 30%, thereby accelerating time-to-market for manufacturers. As businesses strive to optimize their operations amidst rising competition, understanding the impact of the best CNC machines on manufacturing efficiency becomes crucial for maintaining a competitive edge in the global marketplace.

CNC machines, known for their ability to produce intricate parts with minimal human intervention, enhance productivity while significantly reducing waste. In fact, the National Institute of Standards and Technology (NIST) estimates that the adoption of CNC technology can reduce production time by as much as 30%, thereby accelerating time-to-market for manufacturers. As businesses strive to optimize their operations amidst rising competition, understanding the impact of the best CNC machines on manufacturing efficiency becomes crucial for maintaining a competitive edge in the global marketplace.

Benefits of CNC Machines: Revolutionizing Manufacturing Processes

The impact of CNC machines on global manufacturing efficiency is profound, particularly as they integrate with emerging technologies. A recent report indicates that the CNC machine market is projected to significantly expand by 2032, driven by the increased adoption of digital manufacturing technologies. These advancements are not only enhancing productivity across various sectors but are also improving accuracy and reducing operational costs. According to industry insights, around 83% of manufacturers believe that digital solutions will revolutionize production processes within the next five years, underscoring the pivotal role of CNC technology in this transformation.

In addition to digital integration, the incorporation of artificial intelligence and robotics into CNC machining is reshaping the landscape of manufacturing. AI-driven CNC systems are now capable of optimizing operations further, facilitating enhanced precision while streamlining workflows. As the manufacturing sector seeks sustainable practices, these advancements align with efforts to promote a circular economy. The merge of CNC machining with rapid prototyping capabilities illustrates this shift, enabling faster development cycles and material-efficient production. This amalgamation of technologies heralds a new era of efficient, innovative manufacturing processes that are set to redefine industry standards.

Impact of CNC Machines on Manufacturing Efficiency

This chart illustrates the improvements in manufacturing efficiency brought by CNC machines in various sectors. The data reflects the percentage increase in productivity achieved with the adoption of CNC technology over the years.

Enhancing Precision: How CNC Machines Improve Product Quality

In the world of manufacturing, the adoption of Computer Numerical Control (CNC) machines has revolutionized the way products are produced, significantly enhancing precision and quality. CNC machines operate through automated programmed commands, which allows for intricate designs and details to be faithfully replicated in production. This level of precision not only improves the overall quality of the final product but also minimizes waste, as machines can work with tighter tolerances than manual processes. Manufacturers are increasingly recognizing the value of such technology in meeting the demanding standards of modern consumers.

The impact of CNC technology stretches beyond just precision; it also drives efficiency within the manufacturing process. As production timelines shorten and the demand for high-quality components increases, CNC machines allow businesses to respond faster to market needs without sacrificing quality. The growth trajectory of the CNC machinery market is closely tied to this shift towards automation and efficiency, projected to expand significantly as industries seek to enhance their operational capabilities. In essence, the integration of CNC machines not only boosts product quality but also positions manufacturers to compete effectively in an increasingly automated and precision-driven landscape.

Cost Efficiency: Reducing Waste and Increasing Profit Margins

The rise of CNC (Computer Numerical Control) machines has revolutionized the manufacturing sector, and their impact on cost efficiency cannot be overstated. By automating the cutting, shaping, and finishing processes, CNC machines significantly reduce waste, a common challenge in traditional manufacturing methods. With precise programming, these machines ensure that raw materials are utilized optimally, leading to less scrap and a streamlined production process. This not only saves costs associated with excess materials but also minimizes the environmental impact, aligning with the growing focus on sustainable manufacturing practices.

Moreover, the implementation of CNC technology enhances profit margins by increasing production speed and consistency. Unlike manual operations that are prone to human error and variability, CNC machines provide high precision, resulting in products that meet exact specifications every time. This reliability allows manufacturers to rest assured in their quality control, reducing the likelihood of returns or rework, both of which can eat into profits. As a result, businesses can produce more within the same timeframe and improve their bottom line, making CNC machines an invaluable asset in today’s competitive manufacturing landscape.

Flexibility and Customization: Meeting Diverse Industry Needs

The evolution of CNC machines has revolutionized the global manufacturing landscape by offering unparalleled flexibility and customization. Industries ranging from aerospace to consumer electronics require specific solutions that traditional machines can seldom provide. With the best CNC machines, manufacturers can easily adapt to diverse product specifications and design changes without significant downtime. This capability allows companies to respond promptly to market demands, enhancing their competitiveness in an ever-changing global economy.

Tips for maximizing CNC machine flexibility include leveraging advanced software for design and simulation. By using CAD/CAM software, manufacturers can streamline production workflows and quickly prototype various components. Additionally, investing in modular tool systems can enhance adaptability, allowing for quick changes in machining setups without needing extensive reconfiguration.

Another crucial aspect to consider is employee training; skilled operators who understand the intricacies of CNC technology can fully exploit the machine's capabilities. Organizations should prioritize ongoing training programs, ensuring that their workforce is adept at navigating the features that facilitate customization and efficient production, ultimately leading to greater operational efficiency in their manufacturing processes.

What is the Impact of the Best CNC Machine on Global Manufacturing Efficiency - Flexibility and Customization: Meeting Diverse Industry Needs

| Industry Sector | CNC Machine Type | Customization Level | Production Efficiency (%) | Lead Time Reduction (%) |

|---|---|---|---|---|

| Aerospace | 5-Axis CNC | High | 85% | 35% |

| Automotive | Vertical CNC | Medium | 80% | 25% |

| Medical Devices | Milling CNC | Very High | 90% | 40% |

| Electronics | Laser CNC | Medium | 75% | 30% |

| Furniture | CNC Router | Medium | 70% | 20% |

Global Competitiveness: CNC Machines and the Future of Manufacturing

The advent of CNC (Computer Numerical Control) machines has transformed the landscape of global manufacturing, positioning countries to enhance their competitive edge through precision and efficiency. These machines allow for highly automated and accurate production processes, which not only reduce the risk of human error but also significantly increase output rates. As manufacturers adopt advanced CNC technology, they can respond swiftly to market demands and customize products with unparalleled precision, making them more competitive in a world where consumers seek tailored solutions.

Looking ahead, the future of manufacturing is intrinsically linked to the evolution of CNC technology. As manufacturers continue to integrate intelligent systems powered by AI and IoT, CNC machines will become even smarter, learning from production data and optimizing processes in real time. This shift will empower companies to achieve greater efficiency, lower production costs, and faster turnaround times. In a global market characterized by rapid changes and disruptions, those who embrace cutting-edge CNC capabilities will not only thrive but will also set the benchmark for innovation and quality in manufacturing. The implications for global competitiveness are profound, urging industries to invest in these technologies to remain relevant and lead in the future manufacturing landscape.