Mastering CNC Milling and Turning: A Comprehensive Guide for Global Buyers

In the rapidly evolving world of manufacturing, CNC milling and turning have emerged as vital processes that drive precision and efficiency across various industries. According to a report by Research and Markets, the global CNC machine market is expected to reach USD 100 billion by 2025, growing at a CAGR of 7.5%. This surge is indicative of the increasing reliance on advanced machining techniques to enhance production capabilities and meet the demands of today's competitive landscape. Originating from China’s top factories, the mastery of CNC milling and turning not only highlights technological prowess but also instills global trust in product quality and consistency. As buyers look to optimize their supply chains, understanding the intricacies of these machining processes becomes crucial in making informed decisions that align with their operational goals. This comprehensive guide aims to equip global buyers with the essential insights and knowledge needed to navigate the complexities of CNC milling and turning, ensuring they leverage the full potential of these innovative manufacturing solutions.

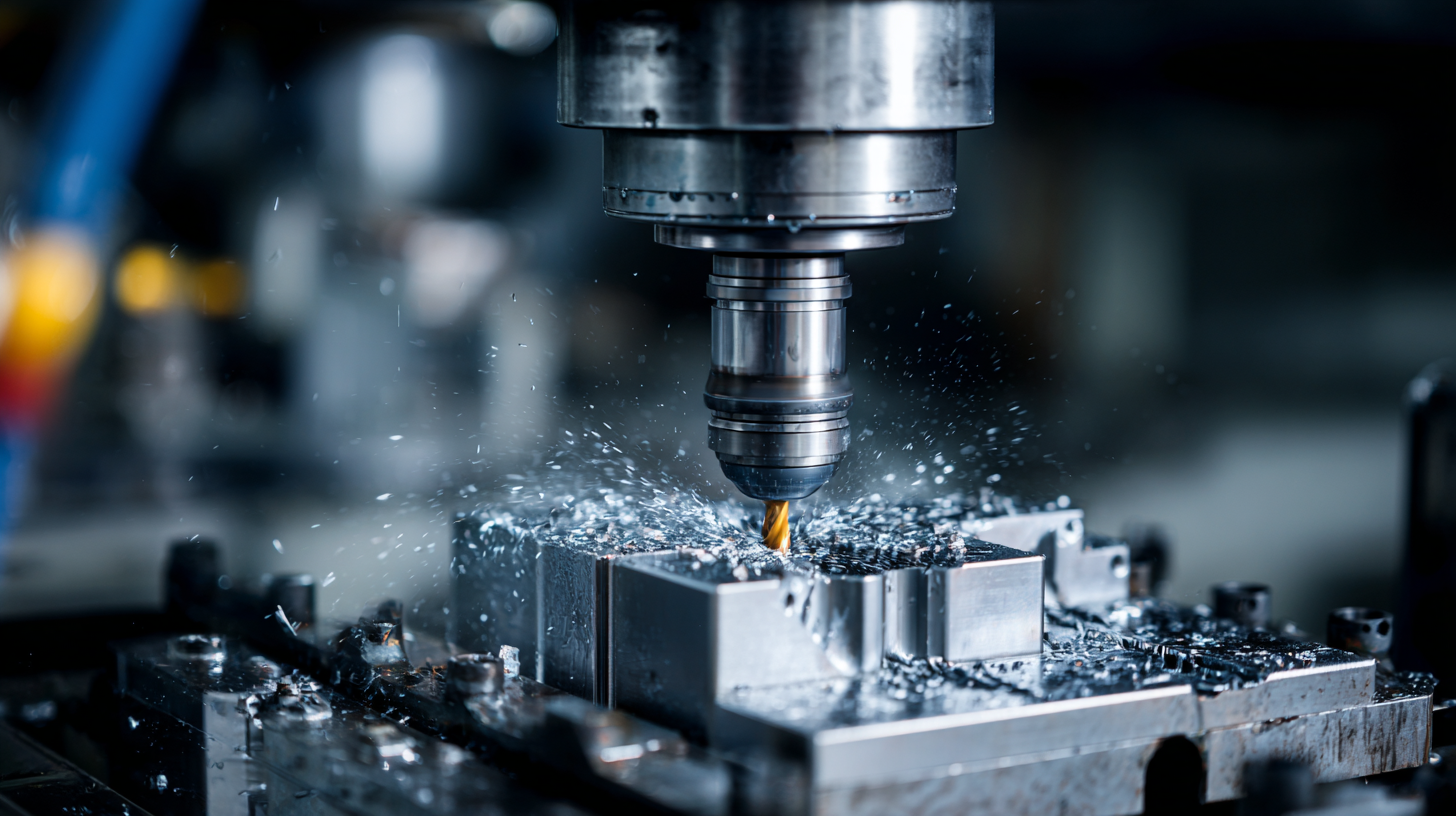

Exploring the Versatile Applications of CNC Milling in Various Industries

CNC milling technology has become a cornerstone in modern manufacturing, offering precision and versatility across various industries. According to a report by MarketsandMarkets, the global CNC machining market is expected to reach $117.25 billion by 2025, growing at a CAGR of 6.18%. This growth is driven by the increasing demand for automation and the need for enhancing productivity, particularly in sectors such as automotive, aerospace, and medical device manufacturing.

CNC milling technology has become a cornerstone in modern manufacturing, offering precision and versatility across various industries. According to a report by MarketsandMarkets, the global CNC machining market is expected to reach $117.25 billion by 2025, growing at a CAGR of 6.18%. This growth is driven by the increasing demand for automation and the need for enhancing productivity, particularly in sectors such as automotive, aerospace, and medical device manufacturing.

In the automotive industry, CNC milling is utilized for producing complex components with tight tolerances, which are essential for both functionality and safety. For instance, a specific study highlighted that approximately 70% of parts in modern vehicles are machined using CNC technology. Similarly, in the aerospace sector, where lightweight and durable materials are critical, CNC milling allows for intricate designs that improve the overall performance of aircraft. It's estimated that the aerospace segment will account for a significant portion of the CNC machining market, reflecting the growing trend towards advanced manufacturing techniques in order to achieve efficiency and reduce waste.

These applications illustrate the transformative impact of CNC milling in various industries, showcasing its ability to improve product quality and optimize manufacturing processes. As global buyers explore CNC solutions, understanding these industry-specific applications can aid in making informed investment decisions.

Real-World Success Stories: CNC Turning Innovations Across Sectors

The application of CNC turning technologies has revolutionized manufacturing across various sectors, showcasing innovative solutions that enhance productivity and precision. For instance, according to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.65 billion by 2025, growing at a CAGR of 6.6%. This growth underscores the expanding reach of CNC turning innovations that cater to diverse industries like aerospace, automotive, and medical devices, which rely heavily on precision machining.

Real-world success stories highlight how companies leverage these advancements to gain a competitive edge. For example, aerospace manufacturers have adopted CNC turning operations to produce complex components with stringent tolerances. A case study by the National Institute of Standards and Technology (NIST) reveals that one aerospace company improved its machining efficiency by 30% through the implementation of advanced CNC turning techniques. Such innovations not only lead to cost savings but also enhance product quality, turning challenges into opportunities for growth and sustainability.

Real-world success stories highlight how companies leverage these advancements to gain a competitive edge. For example, aerospace manufacturers have adopted CNC turning operations to produce complex components with stringent tolerances. A case study by the National Institute of Standards and Technology (NIST) reveals that one aerospace company improved its machining efficiency by 30% through the implementation of advanced CNC turning techniques. Such innovations not only lead to cost savings but also enhance product quality, turning challenges into opportunities for growth and sustainability.

Essential Factors to Consider When Sourcing CNC Milling and Turning Equipment

When sourcing CNC milling and turning equipment, several essential factors should be at the forefront of a buyer's mind. First and foremost is the precision and accuracy of the machinery. High-quality equipment ensures tight tolerances and superior finish, which are critical for industries that demand excellence, such as aerospace and automotive. It’s crucial to evaluate the manufacturer's specifications and, if possible, request sample outputs to assess the machine’s performance.

Another important consideration is the level of technical support and after-sales service the supplier offers. CNC machines are complex, and having access to responsive customer support can significantly minimize downtime during production. Additionally, consider the availability of spare parts and the supplier's reputation for reliability. A well-established provider is more likely to offer long-term support and maintain a sufficient inventory of components to assist in keeping your operations smooth and efficient.

These factors combined can lead to a well-informed decision that ensures a successful investment in CNC milling and turning equipment.

A Step-by-Step Guide to Selecting the Right CNC Machining Partner

In recent years, the global CNC machine market has been on a remarkable growth trajectory, projected to expand from $101.2 billion in 2025 to an impressive $195.59 billion by 2032, with a compound annual growth rate (CAGR) of 9.9%. This significant increase underscores the rising demand for precision machining solutions across various industries. As buyers seek to navigate this dynamic market, selecting the right CNC machining partner has become a crucial step in ensuring operational efficiency and product quality.

One of the most common applications for collaborative robots in the CNC industry is in machine loading and unloading tasks. Unlike human operators, robots do not experience fatigue and can work continuously without significant breaks, enhancing productivity. Moreover, the programmability and automation capabilities of robots streamline these processes, ultimately leading to reduced cycle times and increased output. For global buyers, understanding the technological advancements in CNC machining is essential when evaluating potential partners, as these innovations can significantly impact overall manufacturing performance.

Maximizing Efficiency: Best Practices for Utilizing CNC Technology in Production

In the fast-evolving landscape of manufacturing, maximizing efficiency through CNC technology is paramount for global buyers. Implementing best practices in CNC milling and turning can significantly streamline production processes and enhance output quality. One effective approach is to invest in advanced software that optimizes machining paths and reduces cycle times. By utilizing features like simulation and toolpath analysis, manufacturers can identify potential issues before the actual production begins, saving both time and resources.

Another key practice is to ensure that machines are regularly maintained and calibrated. A well-maintained CNC machine operates at peak performance, which minimizes downtime and extends the lifespan of the equipment. Regular training for operators also plays a vital role; skilled operators are capable of making real-time adjustments and can troubleshoot common issues, further boosting efficiency. Finally, fostering a culture of continuous improvement and encouraging feedback from the production team can lead to innovative ideas that enhance productivity and workflow within the CNC environment.