How to Choose the Right CNC Mill for Your Business Needs

Choosing the right CNC mill for your business is a critical decision that can impact productivity, cost-efficiency, and the quality of your final products. According to a report by MarketsandMarkets, the global CNC milling machine market is projected to reach $23.92 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.2% from 2020 to 2025. This growth underscores the increasing reliance on CNC machining technology across various industries, including aerospace, automotive, and manufacturing.

Selecting the best CNC mill involves understanding your specific production requirements, such as material types, part complexity, and volume. Furthermore, advancements in CNC technology, such as improved automation and precision features, offer businesses the opportunity to enhance their operational efficiency. Therefore, navigating the plethora of options available in the market is essential for aligning your CNC mill choice with your strategic business objectives.

Selecting the best CNC mill involves understanding your specific production requirements, such as material types, part complexity, and volume. Furthermore, advancements in CNC technology, such as improved automation and precision features, offer businesses the opportunity to enhance their operational efficiency. Therefore, navigating the plethora of options available in the market is essential for aligning your CNC mill choice with your strategic business objectives.

Understanding the Different Types of CNC Mills and Their Applications in Manufacturing

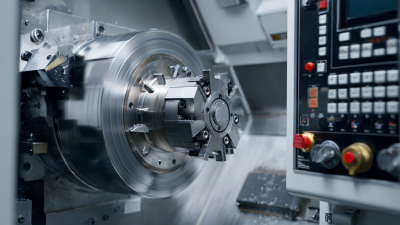

When selecting a CNC mill for your business needs, it is essential to understand the various types available and their specific applications in the manufacturing process. CNC mills can be categorized into different types, including vertical mills, horizontal mills, and universal mills. Each type offers unique advantages depending on the complexity and precision of the parts being produced. For instance, vertical mills are often used for their versatility in drilling and milling operations, making them ideal for small to medium-sized job shops.

Moreover, the adoption of CNC machining technology is transforming the manufacturing landscape by enhancing precision and efficiency in part processing. This technology allows manufacturers to optimize milling parameters, leading to improved productivity across diverse industries. As industry growth forecasts suggest a substantial increase in the CNC machines market, projected to reach USD 170.4 billion by 2033, understanding the specific functionalities and applications of these different types of CNC mills will be critical for businesses aiming to leverage these advancements effectively.

How to Choose the Right CNC Mill for Your Business Needs

| Type of CNC Mill | Applications | Material Compatibility | Precision Level | Typical Price Range |

|---|---|---|---|---|

| Vertical CNC Mill | Drilling, milling, and boring operations | Metals, plastics, composites | High precision (up to ±0.002 inches) | $10,000 - $150,000 |

| Horizontal CNC Mill | Large production, complex parts | Metals, heavy-duty materials | Precision moderate (up to ±0.005 inches) | $15,000 - $200,000 |

| CNC Router | Woodworking, engraving, plastic cutting | Wood, MDF, plastics | Lower precision (up to ±0.02 inches) | $5,000 - $50,000 |

| CNC Mill-Turn | Complex geometries, multi-tasking | Metals, plastics | High precision (up to ±0.001 inches) | $20,000 - $250,000 |

Evaluating Key Specifications: Size, Power, and Precision for Your CNC Mill Selection

When selecting a CNC mill for your business, evaluating key specifications such as size, power, and precision is crucial to ensure it meets your operational requirements. The size of the CNC mill directly affects the type and scale of projects it can handle. Consider not only the physical dimensions of the machine but also the size of the workpieces you will be machining. A larger mill may offer the flexibility to tackle bigger projects, while a compact machine could be more efficient for smaller tasks, optimizing space in your workshop.

Power is another vital specification that influences the mill's performance. A machine with higher horsepower can tackle tougher materials and more complex operations, significantly enhancing productivity. It's important to match the mill’s power with the specific needs of your operations while considering energy consumption and operational costs. Precision is equally important; the accuracy of the milling process determines the quality of the finished products. When assessing precision, look for mills with high repeatability and tight tolerances that are essential for producing intricate designs or components that require exact specifications. Balancing these factors will lead you to the right CNC mill for your business.

Analyzing Cost vs. Benefit: Initial Investment and Long-term ROI of CNC Milling Machines

When selecting a CNC mill for your business, understanding the cost versus benefit is paramount. The initial investment in a CNC milling machine can vary widely, depending on the machine's capabilities, size, and brand.

Businesses should carefully evaluate their production requirements and how different machines will impact their workflow. A higher upfront cost might seem daunting, but it could lead to enhanced productivity, precision, and a broader range of operations.

Long-term return on investment (ROI) is equally crucial in this decision-making process. While some machines may offer a lower purchase price, they could incur higher maintenance costs or produce inferior quality output that necessitates rework. Companies should consider factors such as

operational efficiency, energy consumption, and labor costs. A machine that demonstrates longevity and reliability in performance will ultimately contribute to profit margins, making it a wise investment despite its initial expense.

By thoroughly analyzing these elements, businesses can make informed choices that align with their financial goals and production needs.

The Importance of Material Compatibility: Choosing a CNC Mill for Diverse Materials

When selecting a CNC mill for your business,

material compatibility plays a crucial role in ensuring optimal

performance and efficiency. According to a 2021 report by IBISWorld, the CNC milling industry has grown

significantly, driven by an increasing demand for precision machining across various sectors, including

aerospace, automotive, and medical manufacturing. Each of these applications requires the capability to work

with diverse materials, from aluminum and titanium to advanced composites and

plastics. Understanding the specific material properties, such as hardness, tensile strength, and thermal

conductivity, is essential for choosing a CNC mill that can handle the range of materials your projects demand.

When selecting a CNC mill for your business,

material compatibility plays a crucial role in ensuring optimal

performance and efficiency. According to a 2021 report by IBISWorld, the CNC milling industry has grown

significantly, driven by an increasing demand for precision machining across various sectors, including

aerospace, automotive, and medical manufacturing. Each of these applications requires the capability to work

with diverse materials, from aluminum and titanium to advanced composites and

plastics. Understanding the specific material properties, such as hardness, tensile strength, and thermal

conductivity, is essential for choosing a CNC mill that can handle the range of materials your projects demand.

Moreover, the material's compatibility with the chosen CNC mill affects not only the machining process but also the final product's quality. A study published by the American Society of Mechanical Engineers highlights that selecting the wrong milling machine can lead to increased wear on tools, subpar surface finishes, and ultimately, production downtime. For instance, if a mill is not designed to efficiently process hard materials, it can result in higher operational costs and decreased productivity. Therefore, businesses must evaluate the machine's specifications, such as spindle speed and feed rates, to ensure that it meets their material processing requirements effectively.

Identifying Your Production Volume Needs: How CNC Mill Capacity Affects Business Efficiency

When considering the right CNC mill for your business, assessing production volume needs is crucial. The CNC machine market, projected to reach USD 170.4 billion by 2033, highlights significant growth driven by digital manufacturing technologies. These advancements facilitate higher productivity across numerous industries, making it essential for businesses to align their CNC milling capabilities with their specific production demands.

For instance, adopting machines like the latest models in the end milling machine market can enhance precision in metalworking. Current market forecasts suggest that the end milling machine sector will see significant developments through 2035, focusing on precision and efficiency. By investing in machines that meet their production volumes, companies can optimize their operational efficiency and remain competitive in a rapidly evolving market. Understanding the capacity of CNC mills not only helps in managing production rates but also impacts overall business strategy, ensuring that investments are aligned with future growth and technological advancements.

Related Posts

-

Unlocking the Advantages of CNC Mill Technology for Precision Manufacturing

-

Understanding Import and Export Certifications for the Best CNC Turning Machine in Today's Market

-

2025 Market Insights: How to Choose the Best CNC Vertical Machining Center for Your Business

-

Exploring the Best CNC Machine Alternatives for Your Manufacturing Needs

-

7 Reasons Why Best CNC Equipment is Essential for Your Global Sourcing Strategy

-

Crafting Excellence with the Best CNC Machines from China for Global Service